DAHAO Magnet Encoder Type Thread Breakage Detection Product

As a basic function of the embroidery control system, the thread breakage detection plays a very important role in the application of the embroidery machine. Traditional thread breakage detection adopts the spring type thread breakage method to identify the thread breakage by the on/off connection of the spring connection loop. The advantages are the upper thread detection is sensitive, the type of thread breakage board is less, and the interface is simple, while the disadvantage is, the bottom thread detection recognition is not that good, and in most cases it is unable to detect and report error.

As increasing of the customer's demand for bottom thread detection, the thread breakage detection gradually develops to the method of detecting by light chopping wheel, which judges the bottom thread status by indirect detection and analysis of the upper thread’s passing status under the condition of no bottom thread. This detection method has a significant improvement in the detection of the bottom thread, and has gradually become the mainstream of the market. However, due to the low accuracy of the light chopping wheel and the insufficient recognition of the jitter error during the thread passing process, error report sensitivity of the overall upper thread breakage is not high (so there is still a need for the spring thread breakage method for assistance), bottom thread breakage detection for some stitch embroidery is not ideal, and there may be false alarm or missing alarm, which have a great impact on the customer's production efficiency. At the same time, there are many types of bottom thread breakage boards and the installation is a little complicated.

In order to further improve the breakage detection sensitivity of the upper and bottom thread, DAHAO developed a new generation of thread breakage detection technology based on the principle of magnetic encoder, which has high detection accuracy and fast response speed, and can identify the thread passing wheel turning direction. After theoretical analysis and long-term practice and improvement, this method can greatly improve the sensitivity of thread breakage detection, and can quickly identify the state of the upper thread breakage and the no bottom thread status, realizing a big step leap in the technology and performance of the embroidery machine thread breakage detection. The ability to thread breakage detection has reached the leading level in the industry, and DAHAO has applied for invention patents of relevant technologies.

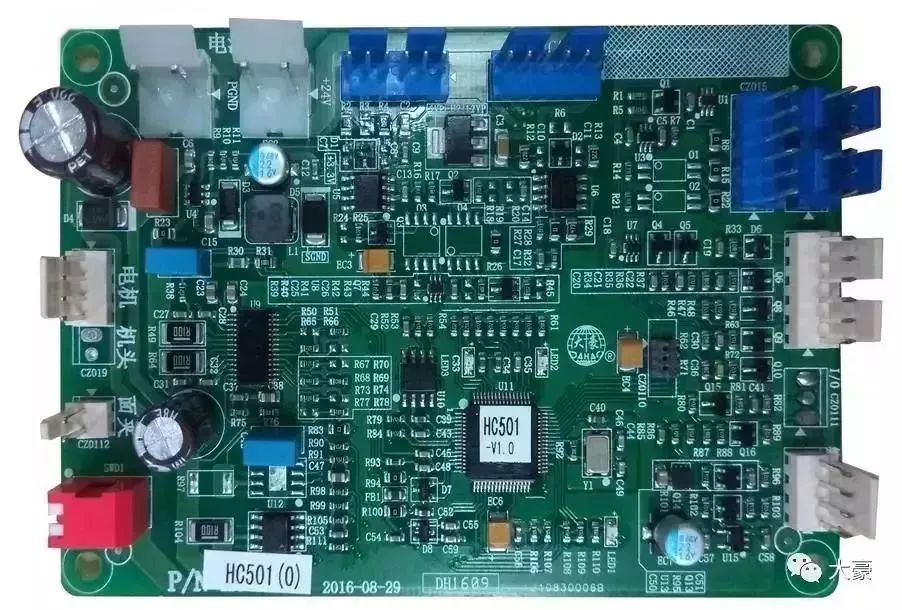

Magnetic Encoder Type Thread Breakage Detection Control Board

1. Giving upper thread breakage alarm within 5-stitches

The upper thread detection uses high-precision sensors and advanced algorithms, which is more sensitive than the spring detection and has a low false alarm rate. Under ideal working conditions, the type III thread breakage needs more than five stitches to give the error report, while the magnetic encode type thread breakage method can realize giving alarm within 5 stitches.

2. Can avoid non-embroidery needle position false alarm

Upper thread Detection adopts no spring contact measurement, avoiding non-embroidery needle position false alarm during the mixed embroidery of metallic yarn and cotton thread in principle.

3. Quickly identify single line no-bottom-thread status

The bottom thread detection is more sensitive than the wheel type, and it can quickly identify the single line no-bottom-thread status, reaching the advanced level in the industry. Under the ideal working condition, the type III bottom thread breakage will takes more than 10 stitches to alarm, while the magnetic encode thread breakage can alarm within 10 stitches.

4. Thread usage statistics function

Accurately calculate the thread usage of each needle position, which is convenient for the manufacturers to debug the machines and for end-users to conduct elaborate embroidery production management and calculate thread consumption amount.

5. Strong anti-dust and oil-proof, easy wiring

Through the magnetic induction non-contact method, it has strong anti-dust and oil-proof ability, and it does not need the bottom thread breakage board or spring type thread breakage signal, so the field wiring is convenient.

The magnetic encoder type thread breakage detection technology is a

breakthrough of traditional technology developed by Dahao, and

applying with the digital control of Dahao's upper thread tension will

bring revolutionary changes to the embroidery industry:

In today's increasingly competitive world, magnetic encoder type thread breakage detection plus thread tension control will bring value to embroidery users.

At present, the single magnetic encoder thread breakage thread holder has 6 needles and 9 needles type. And magnetic encoder type thread breakage detection thread holder with thread tension control has three models---6 needle, 9 needles and 12 needles, only adapted to integrated control system.

END

撰 稿:崔 凯 邢京伟

翻 译\视 频\编 辑:邢京伟

校 核:聂一欣

责 编:徐 斌